Foundation of the company Thermotec AG by Sebastian Heidrich

E-heat is the future – that is our vision. E-heat cleverly used is our mission. Thermotec AG has been an internationally recognized manufacturer and specialist for electric heaters with the “Made in Germany” seal for over 20 years.

With around 50 employees, we develop and produce efficient electric heaters under the “AeroFlow” brand. From the idea to customized plant engineering (production-technical implementation) to worldwide distribution, we combine all steps under one roof for maximum efficiency.

Production, administration, storage and shipping take place on 5,000 m2 of office and hall space. The buildings are located on a former 52,000 m2 quarry site in the middle of the picturesque landscape of Lower Silesian Lusatia between Dresden and Görlitz. Deeply rooted in the region, we develop and produce state-of-the-art electric heaters here in the heart of Europe for worldwide use, primarily within Europe and to China.

E-heat is the future – that is our vision. E-heat cleverly used is our mission. Thermotec AG has been an internationally recognized manufacturer and specialist for electric heaters with the “Made in Germany” seal for over 20 years.

With around 50 employees, we develop and produce efficient electric heaters under the “AeroFlow” brand. From the idea to customized plant engineering (production-technical implementation) to worldwide distribution, we combine all steps under one roof for maximum efficiency.

Production, administration, storage and shipping take place on 5,000 m2 of office and hall space. The buildings are located on a former 52,000 m2 quarry site in the middle of the picturesque landscape of Lower Silesian Lusatia between Dresden and Görlitz. Deeply rooted in the region, we develop and produce state-of-the-art electric heaters here in the heart of Europe for worldwide use, primarily within Europe and to China.

We take responsibility for our actions and make courageous decisions. We act as a team and support each other. Together we convince through the good quality of our work.

Many work processes overlap with those of other departments and work areas. We work together effectively. We attach great importance to mutual openness, objectivity and friendliness in our dealings with each other.

Only those who know their goal can reach it. Therefore, we set clear requirements that we follow consistently. Together we define stages and decide by when we can and want to implement them. Along the way, we keep checking where we are. This is how we achieve our goals.

Clear structures are a high priority for us because they are the prerequisite for professional work. This includes a tidy working environment where everyone has a place and everyone can find their way around. By keeping things tidy, we gain time to focus on what’s important: our work.

To achieve the best possible quality, each production step is subject to constant control. We define measurable quality characteristics and check their compliance objectively. The documentation and evaluation helps us to eliminate deviations. We are only finished when the demands of our customers and our quality requirements are met.

Mistakes can happen. We stand by them and deal with them constructively and appreciatively. This is because they provide us with information, for example, about weak points in the process or possible new approaches to solutions. Together, we get to the bottom of the cause and ensure that the same error does not occur again.

The permanent optimization of our processes and structures is part of our corporate culture. We always want to get better and we are continuously working on that. Our employees are experts in their field and look for causes and solutions for your work area. If asus a proposed solution becomes a measurable improvement, it becomes the new standard.

“The outstanding quality of our products and our processes is the basis of our success. We want to be the best with our performance and not only satisfy our customers, but inspire them. To achieve this, we set ourselves ambitious goals, working towards them with passion and confidence across organizational boundaries. A high level of vertical integration and a process landscape that otherwise only large companies have make us particularly fast – this maintains our independence, of which we are very proud.”

Christian Adams

Management Board of Thermotec AG

Reliable quality management in accordance with DIN EN ISO 9001 ensures consistently high product and service quality. Since 2019 we are certified by TÜV.

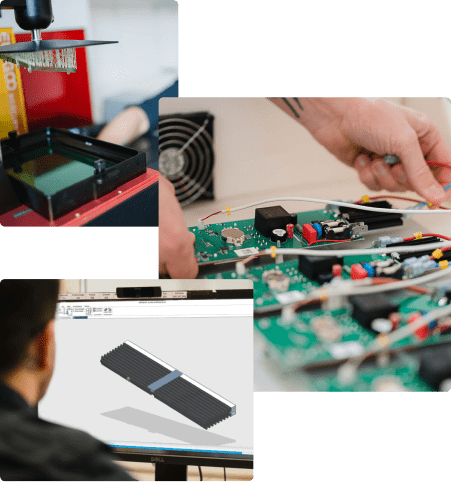

In order to be able to generate continuous growth, we are constantly working on developing new products and innovations. To this end, we hold Ideas Factory workshops at regular intervals. Our development team then turns these ideas into reality by creating drawings, building prototypes and then putting them through their paces until the product meets our high quality requirements.

In addition to our own test benches, a 3D printer or temperature measuring stations, we also have contacts with external institutes (e.g. Leipzig University) that can perform additional tests for us. Ultimately, the focus of any new or further development at Thermotec is always on quality and credibility

of our brand.

“Made in Germany” is not just a slogan for us. It is a seal of quality for goods manufactured in Germany. It is our commitment and constant demand to manufacture high-quality products that satisfy their users for a long time with timeless design and sustainable quality. To achieve this goal, we deliberately avoid outsourcing and subcontractors. Our products are produced by our qualified employees in our factory in Vierkirchen and shipped from there all over the world.

Every single production step at Thermotec is subject to constant quality control. Our goal is to meet the high quality requirements of our customers and to reduce quality fluctuations to a minimum.

In cooperation with scientific institutes, we also ensure that all the technologies we use are always state-of-the-art.

We are sure of our quality:

Regardless of the statutory warranty rights, we as manufacturers provide a warranty for the duration of 30 years on our radiators. You can view the exact warranty conditions here.

Our work processes are clearly defined and allow us to work precisely and economically with a short manufacturing time of our products. The machine automation combined with manual manufacturing results in a good symbiosis and brings high quality and efficiency to our production processes. In addition, a high degree of vertical integration in our company provides us with freedom and minimizes delivery difficulties.

The internally installed lean management is permanently working on improving processes in order to avoid wasting time and materials and to minimize interface problems. We do not leave improvements to chance, but tackle them in a targeted manner together with our employees. Causes become solutions and solutions become improvements.

In order to be able to generate continuous growth, we are constantly working on developing new products and innovations. To this end, we hold Ideas Factory workshops at regular intervals. Our development team then turns these ideas into reality by creating drawings, building prototypes and then putting them through their paces until the product meets our high quality requirements.

In addition to our own test benches, a 3D printer or temperature measuring stations, we also have contacts with external institutes (e.g. Leipzig University) that can perform additional tests for us. Ultimately, the focus of any new or further development at Thermotec is always on quality and credibility

of our brand.

The high-bay and small parts warehouse, which went into operation in 2016, is designed for maximum productivity and efficiency. We stock our products on more than 3,000 m2 of warehouse space, of which more than 1,000 pallet spaces form our buffer warehouse, so that we can deliver our customers their goods on time. Most shipments leave our premises within 48 hours to reach their destination by freight forwarding or parcel service.

In a nutshell: A friendly and ambitious team with a great innovative product! It is simply fun to work with the people and the company and to be able to experience its development.

We have accompanied Thermotec AG with great pleasure and all possible support as a supplier since the beginning. Please keep it up!

The smooth and successful cooperation with the company Thermotec brings continuous joy to our team of RW-elektro.

It is enormously motivating to rely on such an effective range of products that combine technology, benefits, clear advantages and timeless design so well, with also short delivery times for immediate and effective use. Ultimately, after all, it's all about our satisfied customers, who can clearly rely on German manufacturer quality.

We would like to express our sincere thanks that we, as a sales partner, can rely not only on the products, but also on all-round concerns from a dealer's point of view with Thermotec. Keep it up!

The former EH Switzerland and now e-heating systems Kolano are extremely taken with the quality and variety of Thermotec AG's product range.

We were able to see this for ourselves at the plant.

We are particularly excited that all parts are developed and manufactured in-house. We are thrilled that the delivery times are met, resp. are foreseeably short.

We are convinced that this innovative team will continue to develop new things in the future and we will enjoy working with the company.

In a nutshell: A friendly and ambitious team with a great innovative product! It is simply fun to work with the people and the company and to be able to experience its development.

We have accompanied Thermotec AG with great pleasure and all possible support as a supplier since the beginning. Please keep it up!

The smooth and successful cooperation with the company Thermotec brings continuous joy to our team of RW-elektro.

It is enormously motivating to rely on such an effective range of products that combine technology, benefits, clear advantages and timeless design so well, with also short delivery times for immediate and effective use. Ultimately, after all, it's all about our satisfied customers, who can clearly rely on German manufacturer quality.

We would like to express our sincere thanks that we, as a sales partner, can rely not only on the products, but also on all-round concerns from a dealer's point of view with Thermotec. Keep it up!

The former EH Switzerland and now e-heating systems Kolano are extremely taken with the quality and variety of Thermotec AG's product range.

We were able to see this for ourselves at the plant.

We are particularly excited that all parts are developed and manufactured in-house. We are thrilled that the delivery times are met, resp. are foreseeably short.

We are convinced that this innovative team will continue to develop new things in the future and we will enjoy working with the company.

Our quality has its price: The Allgemeine Unternehmen Verband Görlitz und Umgebung e.V. awarded us the Entrepreneur Award in June 2015. With this award, the Entrepreneurs’ Association honors regional entrepreneurs who have a special development to show.

Foundation of the company Thermotec AG by Sebastian Heidrich

Construction of a 1,100 m2 production hall at the Friedersdorf site

Extensive investment in machinery, including a lamella press for the radiators

Construction and installation of an automated welding line for font and back panels

Thermotec GmbH becomes Thermotec AG

Relocation from Friedersdorf to Arnsdorf, Vierkirchen with 53,000 m2 of land and 2,000 m2 of production and office space

Thermotec is awarded the East Saxony Entrepreneur Award

Commissioning of the new warehouse with a radiator storage of 3,000 m2 storage area.

Christian Adams becomes new head of Thermotec Strategic realignment of the company

Start of the Lean Management Project

Production of the 100,000. Heating (10.04.2019)

Expansion of the export business and internationalization of sales, further automation of production

Implementation of a service life test bench for testing the heating control system under stress conditions

In planning: fully automated welding system for front and rear panels

Thermotec AG

Arnsdorf 26

02894 Vierkirchen

Thermotec AG

Arnsdorf 26

02894 Vierkirchen